0102030405

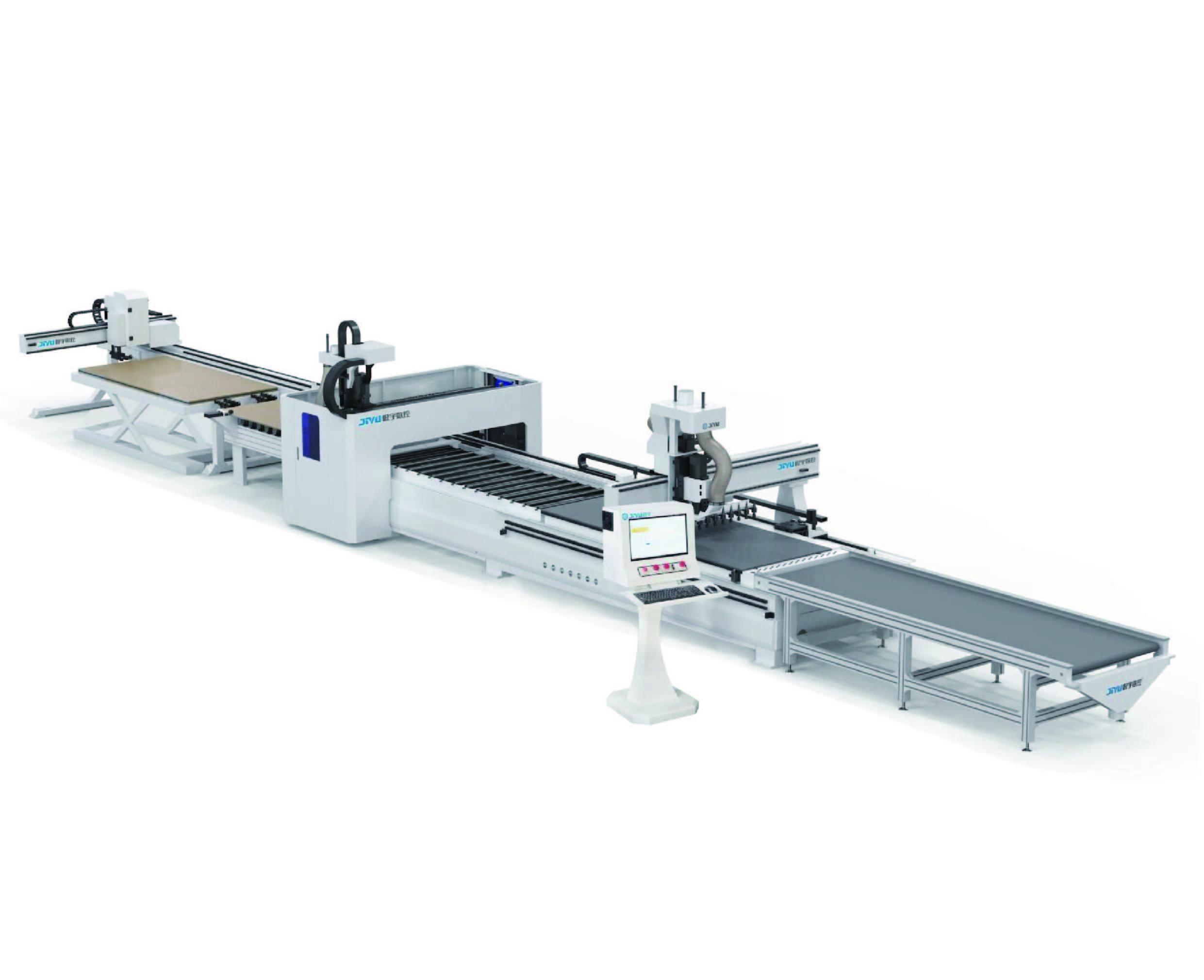

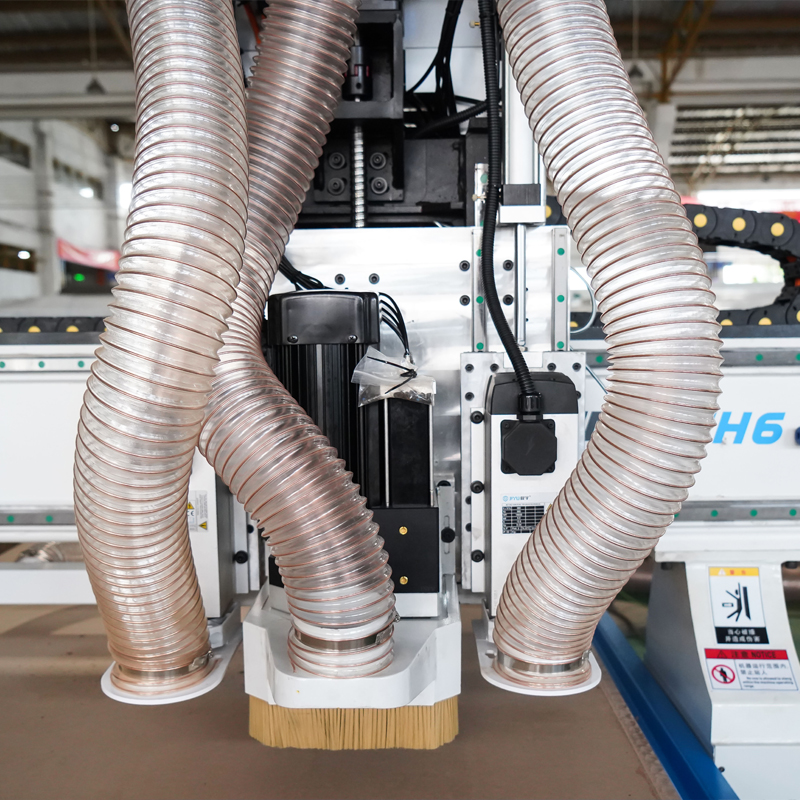

CH6 CNC Cutting Machine (Double spindle & drilling package)

Processing unit

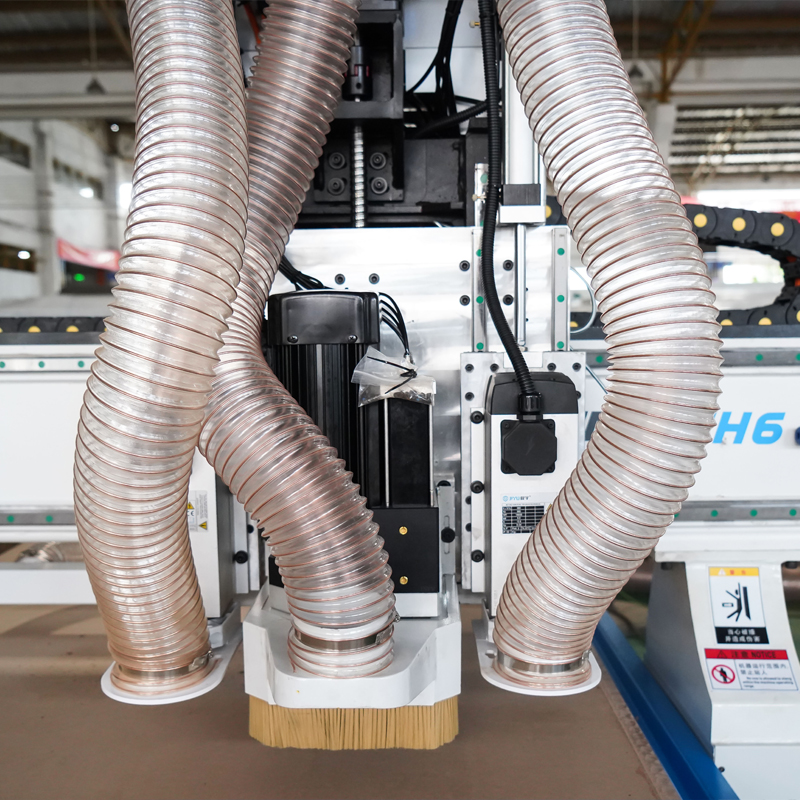

Spindle: Two 6kw high-speed electric spindle are used; with one drilling package

Maximum speed: 18000rpm

Tool change method: Manual

High precision, long life, stable work.

Maximum speed: 18000rpm

Tool change method: Manual

High precision, long life, stable work.

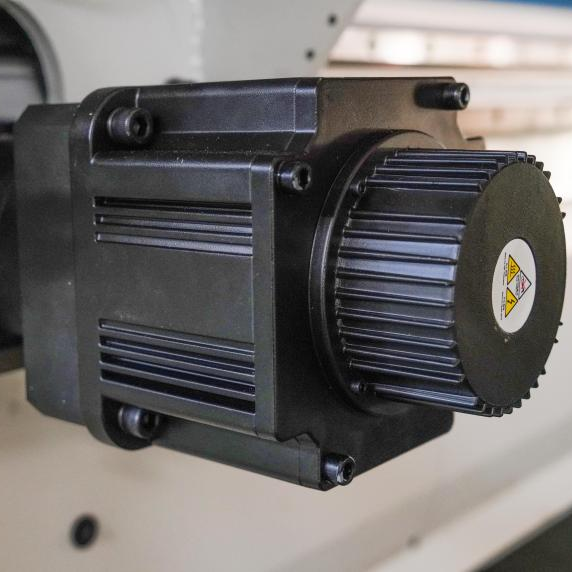

Servo Motors and Drivers

The drives of each axis use high-quality servo motors of well-known brands to ensure the precise displacement of each axis and the precision of the equipment.

Gears and Racks

The X/Y axis is driven by helical gears, which has large bearing capacity and high precision, and is more durable than traditional spur gears.

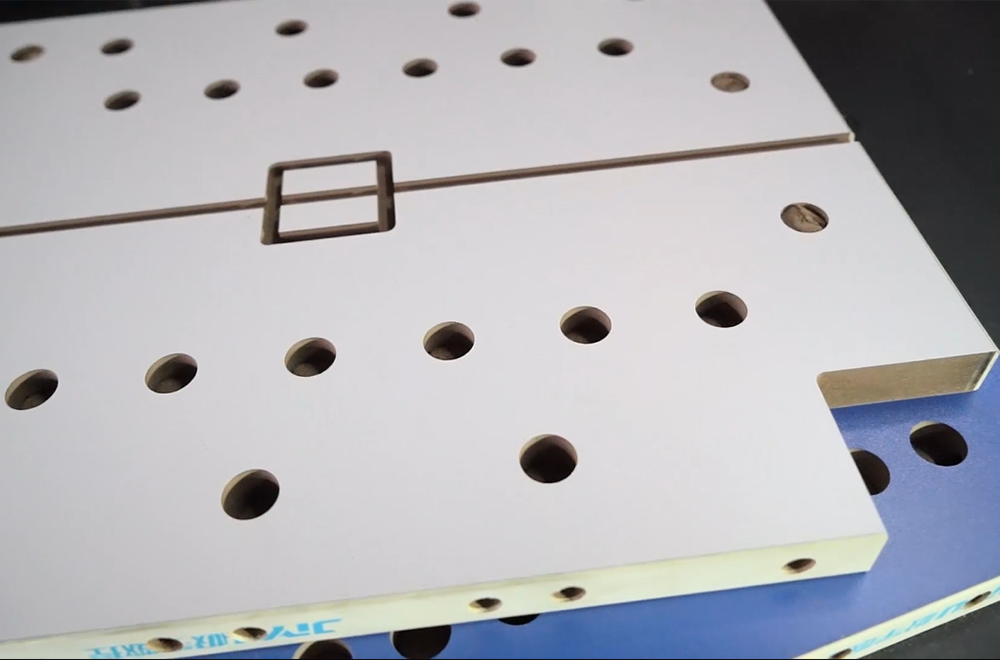

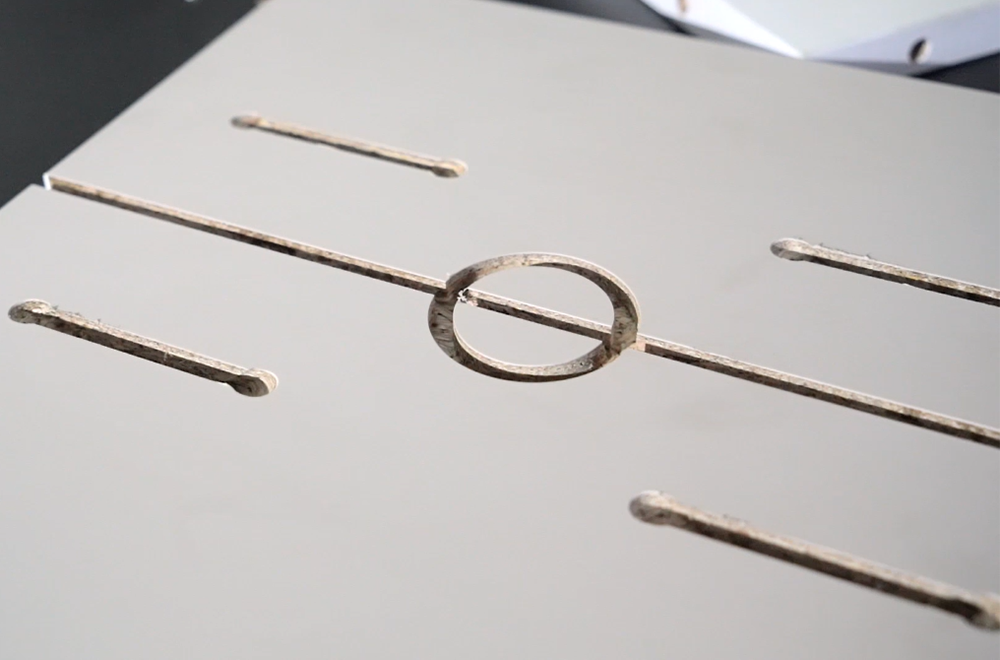

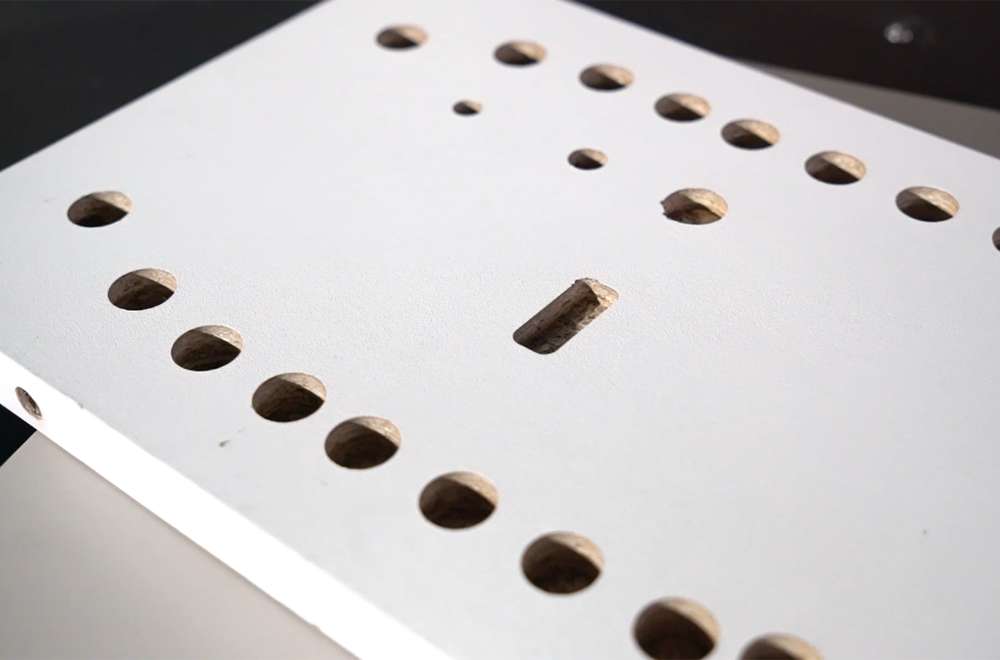

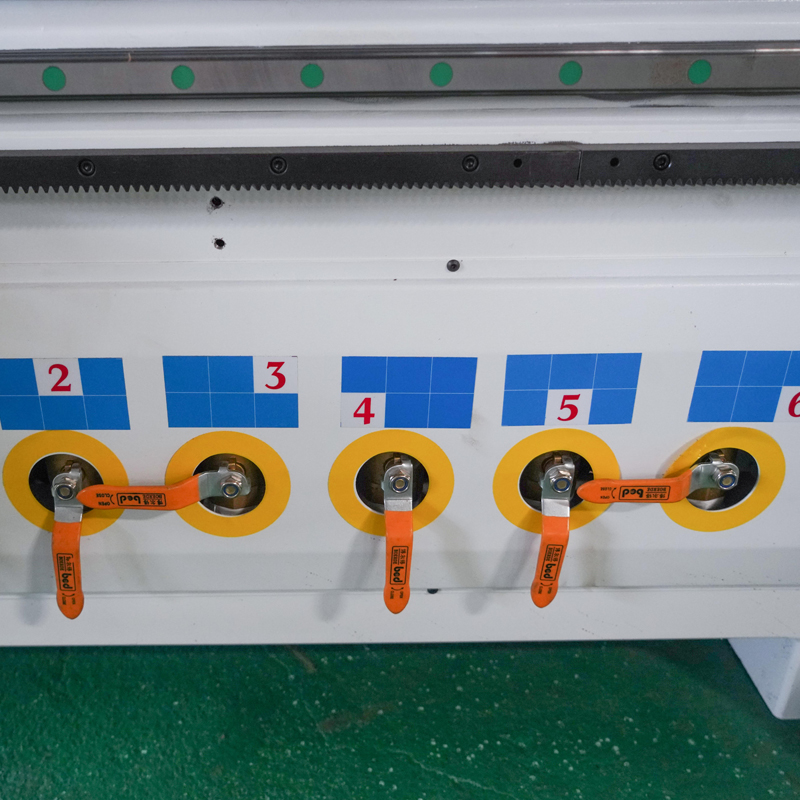

Adsorption table

Suction table Matrix polyester table top and MDF. The adsorption area is divided into four groups, and the adsorption table area can be opened and closed manually according to the size of the plate.

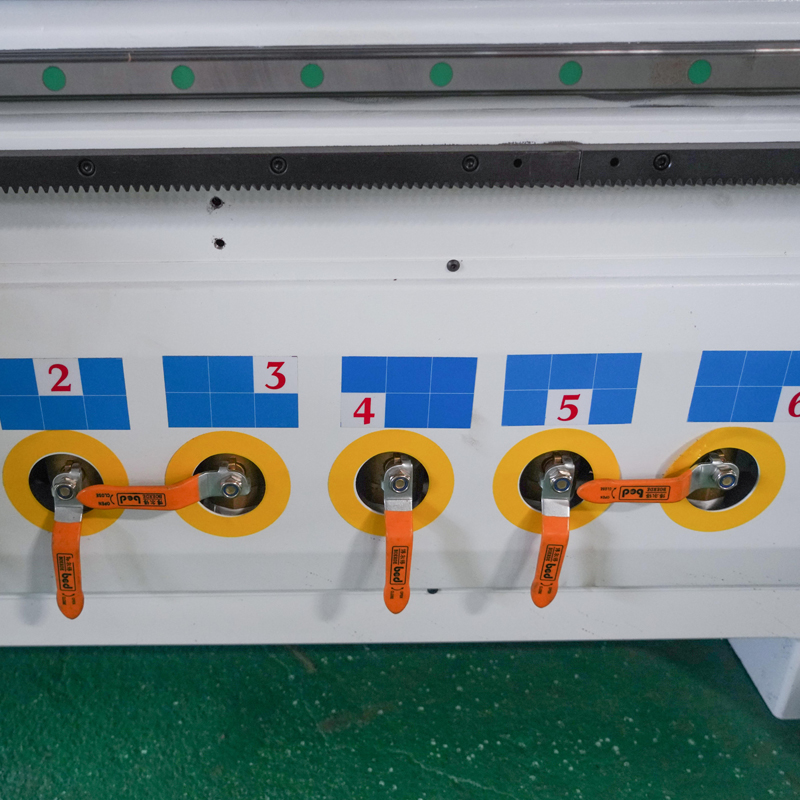

Vacuum area control

The vacuum area of the entire working surface is controlled by 6 independent switches, which can complete the processing of various workpieces and make reasonable use of the suction board space.

Drag chain

The Igus drag chain imported from Germany has a long service life and effectively protects the cables from wear and tear.

Lubrication system

The machine is equipped with an automatic oil injection lubrication system to ensure machining accuracy and prolong service life.

Vacuum pump

Equipped with 7.5KW vacuum pump. cooling method: water circulation.

Inverter

Adjustable frequency conversion 7.5KW

Guide rail

German Ferrante guide rail 30 square rails (Y axis)