The differences and connections between panel furniture and solid wood furniture

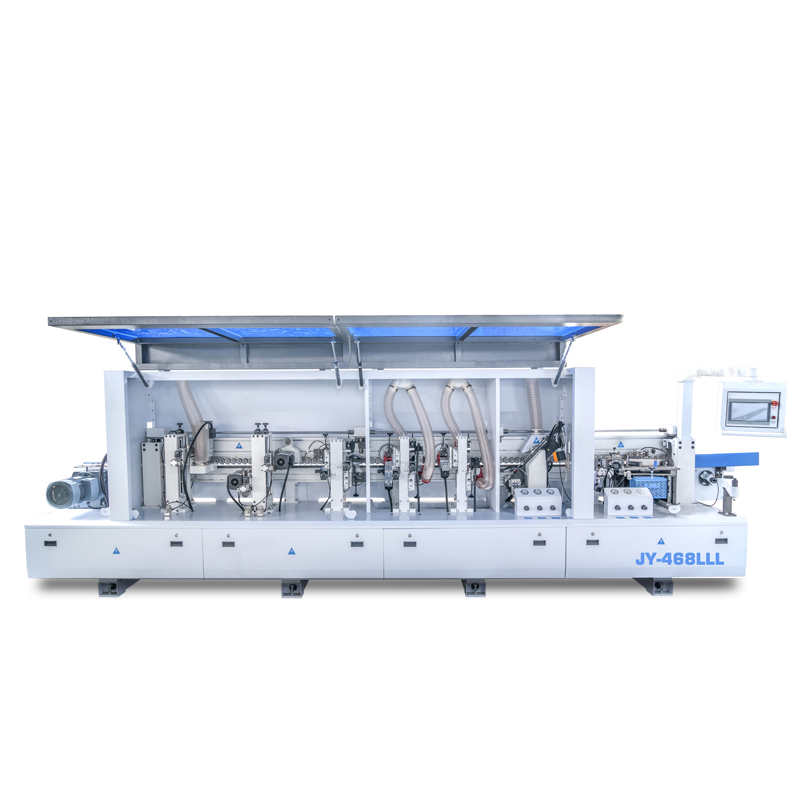

The following is a guide on how to maintain the edge banding machine:

1. Regularly clean the machine: Make sure to keep the machine free from dust and debris by using a damp cloth or vacuum cleaner.

2. Check the temperature of the heat roll: Maintaining a constant heat temperature is crucial for the edge banding process. Therefore, always ensure that the heat roll is at a consistent 200 degrees.

3. Inspect the edge banding tape: It is essential to maintain the quality and integrity of the edge banding tape. If the tape has damage, replacing it as soon as possible is crucial.

4. Lubricate the machine regularly: The moving parts of the edge banding machine, such as the roller and gears, should be oiled every 400 hours to reduce friction and prevent wear and tear.

5. Tighten screws: If you notice any loose screws or parts, ensure to tighten them immediately to prevent further damage.

6. Perform regular maintenance: It is recommended to perform regular maintenance and check the machine's functions to detect any possible faults, including adjustments of the edge banding machine, cleaning the conveyor belt, and routine cleaning of the machine.

7. Always follow the safety instructions: To ensure your safety, always follow the manufacturer's safety instructions and wear the proper safety equipment when operating the edge banding machine.

Following these simple maintenance tips can help keep your edge banding machine functioning at its best, prolong its lifespan, and prevent unnecessary wear and tear.

From the earliest definition, the difference between panel furniture and solid wood furniture is:

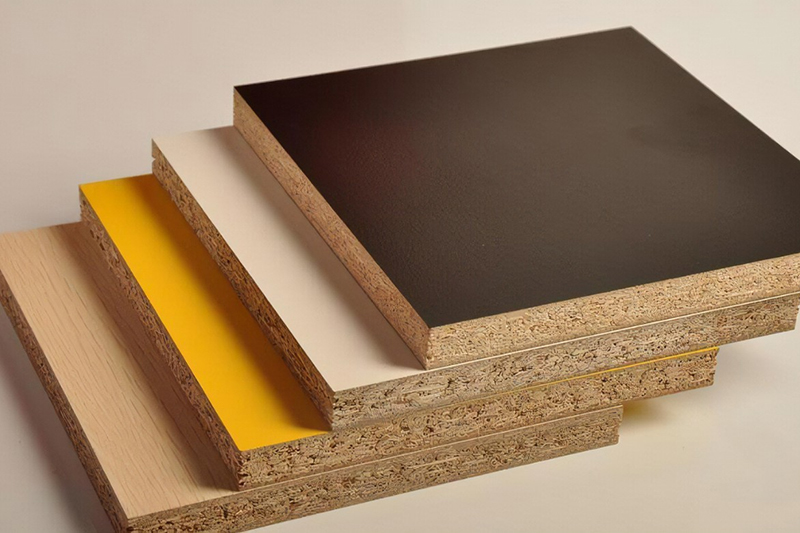

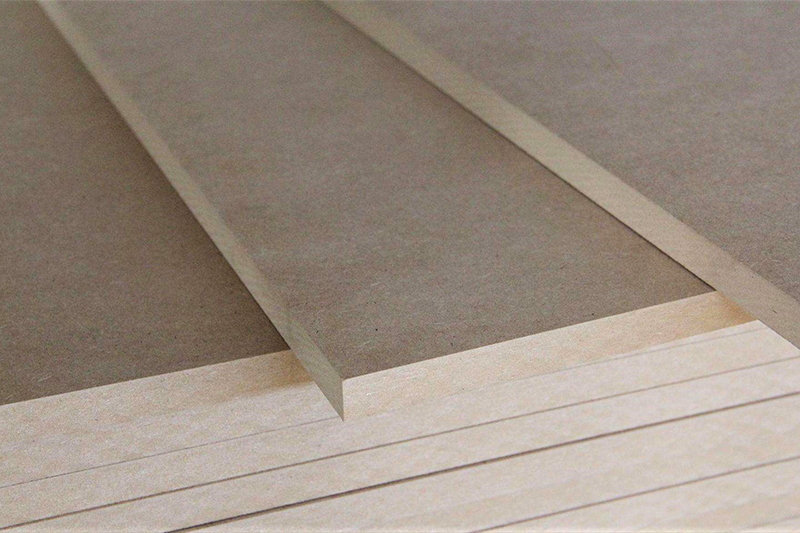

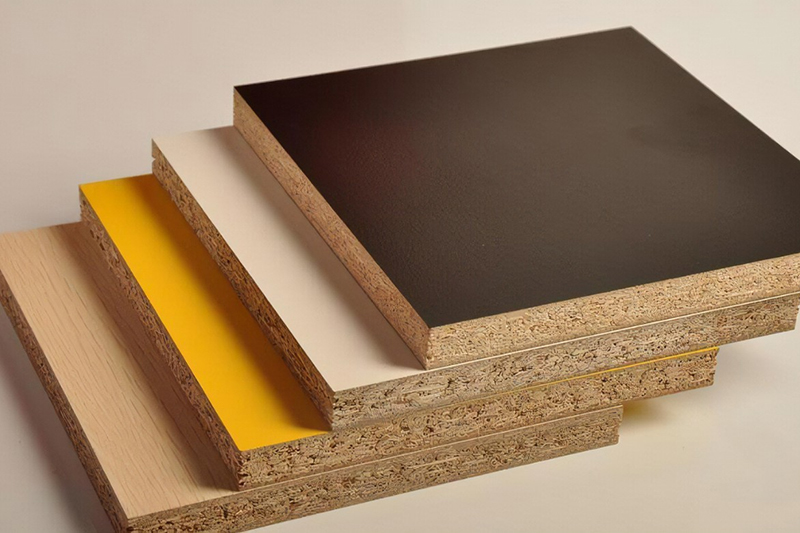

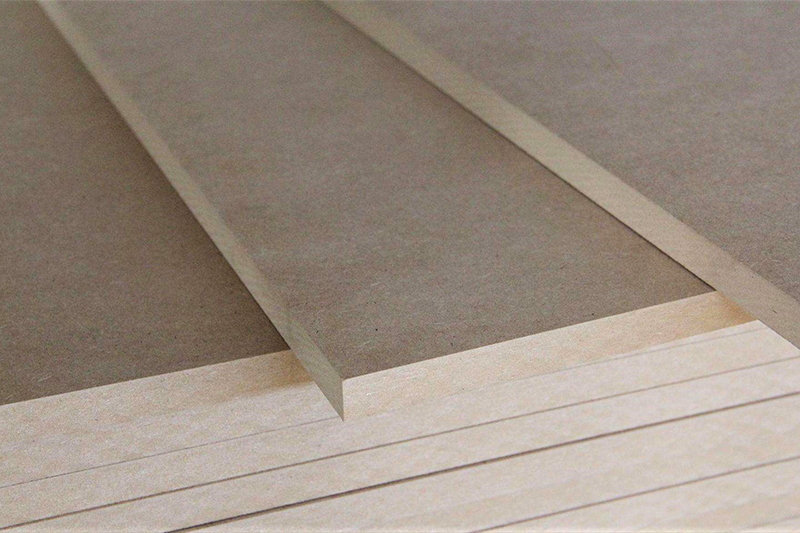

1. Materials. The base material of panel furniture is artificial board, which mainly refers to density board, particleboard and plywood; the base material of solid wood furniture is solid wood, including various types of broadleaf and coniferous wood.

2. Structurally. Panel furniture is a disassembly structure, with hardware connectors as the core and various corresponding hole nodes used to assemble various panels together to form furniture; solid wood furniture is frame furniture, which is non-detachable and is generally It's a makeover.

However, today's panel furniture and solid wood furniture are intersecting more and more, and their integration is getting better and better. In terms of structure, many solid wood furniture have changed the frame structure into a disassembly structure, and many processing equipment (such as: panel furniture cutting machine, customized furniture cutting machine, wardrobe cutting machine and cabinet cutting machine). The methods and processing requirements are the same as those for panel furniture. In terms of materials, most solid wood office furniture is partially made of artificial panels, which are mainly used in large-area flat parts.

It has high processing efficiency and low cost. It can achieve the effect of solid wood by pasting wood veneer and inlaying solid wood edges. It can be said that solid wood office furniture has become plate-type, and plate-type office furniture has become solid wood. In order to change the single face of panel office furniture and enhance its styling space and added value, many panel office furniture adopts the wood veneer process, and some partial structures also use solid wood parts to enhance the richness of the shape and the texture of the wood. In this way, panel office furniture has become very common and is loved by consumers.

In short, the panel CNC furniture cutting machine has won more than half of the world with its high efficiency, high precision and high mechanization. However, it still has shortcomings that are currently difficult to overcome, mainly the release of formaldehyde and other organic volatiles (The nail-holding force of the artificial board is relatively small, and the board-type furniture will easily loosen after being used for a long time, affecting the stability) and the problem of yellowing of the paint, the problem of paint peeling, the problem of the edge strips being glued apart, the separation of various decorative materials from the base material, etc.

The safety, comfort, durability and decoration of solid wood furniture are unmatched by panel furniture. However, the stability of solid wood is slightly worse. It is its nature to shrink with dryness and expand with moisture, which is difficult to overcome. In addition, the yield rate of solid wood is low and the cost is much higher than that of panel furniture. Moreover, the reserves of solid wood are becoming less and less, and countries are restricting the export of logs. The source and price of solid wood are facing challenges.