Revolutionizing manufacturing with smart boring machines

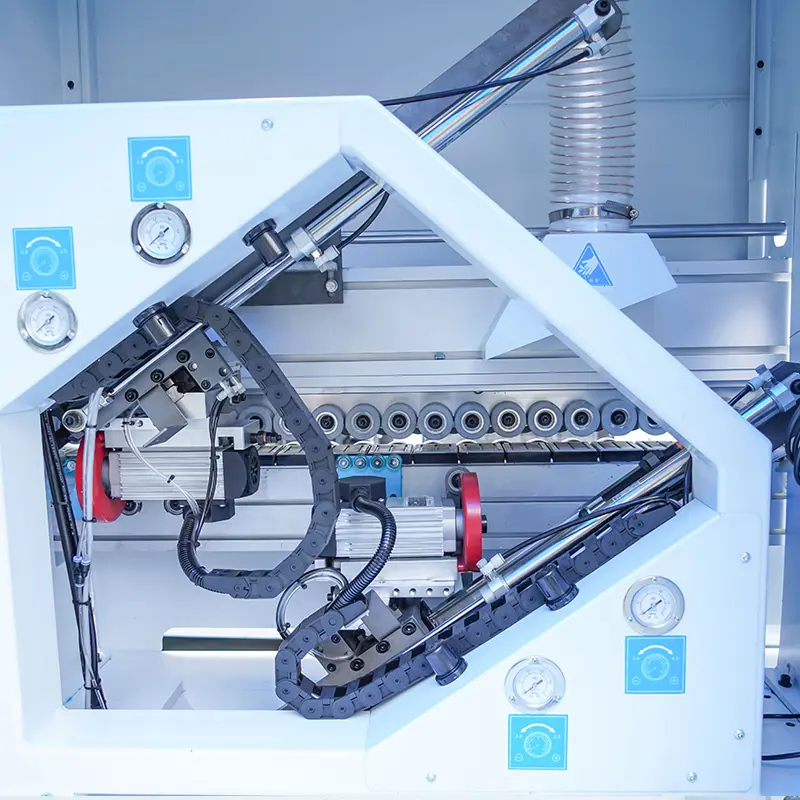

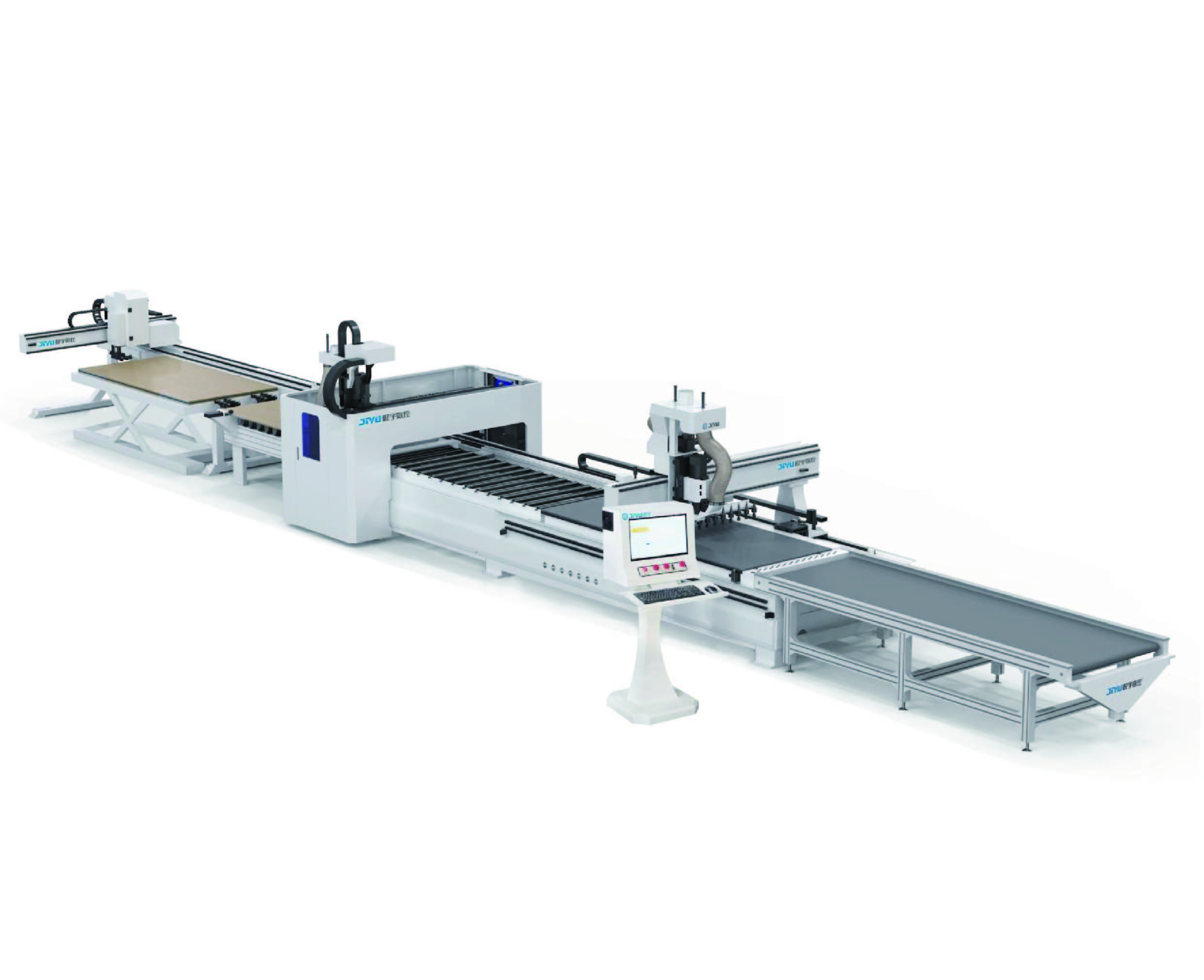

In the manufacturing world, efficiency and precision are key factors that determine the success or failure of a business. This is where the innovative technology of smart boring machines comes into play. These machines are equipped with advanced industrial control computers, scan code processing and automatic chain conveyors, making them game changers in the industry.

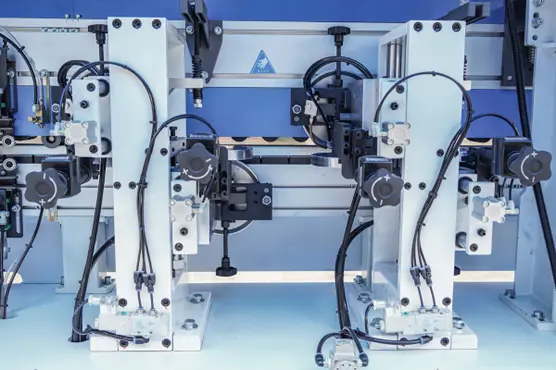

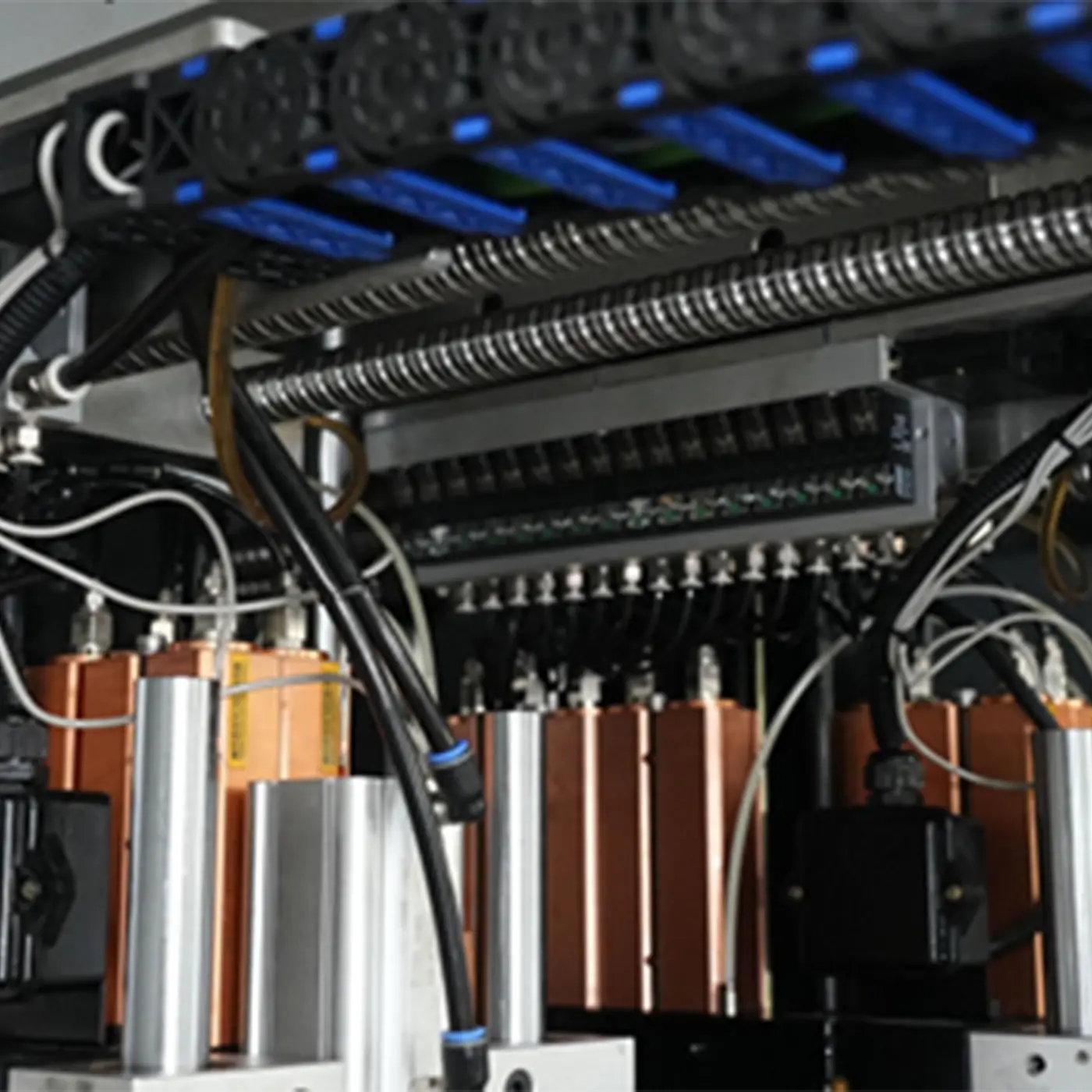

The use of intelligent industrial control computers in boring machines has revolutionized the manufacturing process. These computers are capable of processing complex instructions and executing them with unparalleled accuracy. This means that five sides of the workpiece can be drilled in one operation, eliminating the need for multiple setups and reducing the margin for error. The result is significantly faster processing and more efficient workflows.

Additionally, integrated scan processing technology enables seamless communication between machine and operator. This not only simplifies the set-up process but also ensures the machine operates at optimal efficiency throughout the entire production process. The ability to automatically transport workpieces during the drilling process further increases the overall speed and efficiency of the operation.

The impact of smart row drilling rigs is far-reaching. Manufacturers are now able to take on more complex projects with confidence knowing that these machines can handle complex drilling tasks with ease. This not only expands the manufacturing facility's capabilities but also opens up new opportunities for growth and diversification.

In summary, the combination of smart industrial control computers, scan code processing and automated chain conveyors in row boring machines has changed the manufacturing landscape. Process faster, your workflow is more efficient, and the possibilities are endless. As technology continues to advance, the potential for further innovation in this area is limitless, leading to an even more exciting future for manufacturing.