0102030405

Introduction to cutting machine technology

2023-12-05

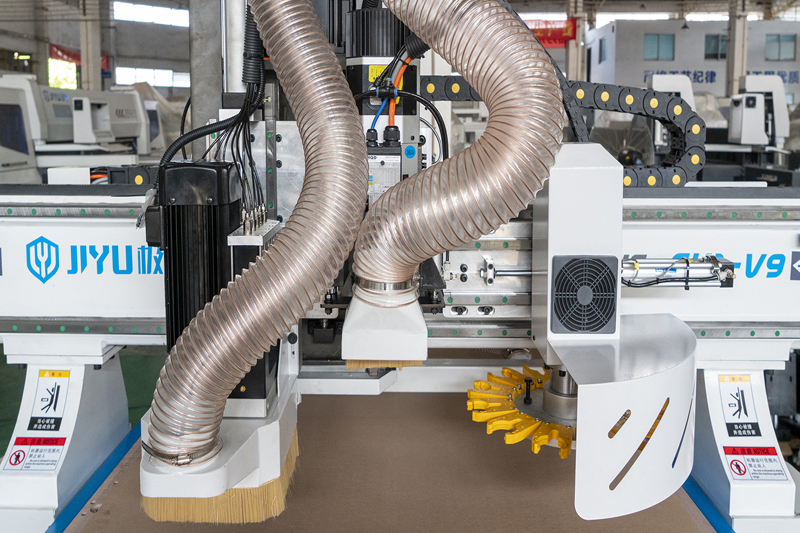

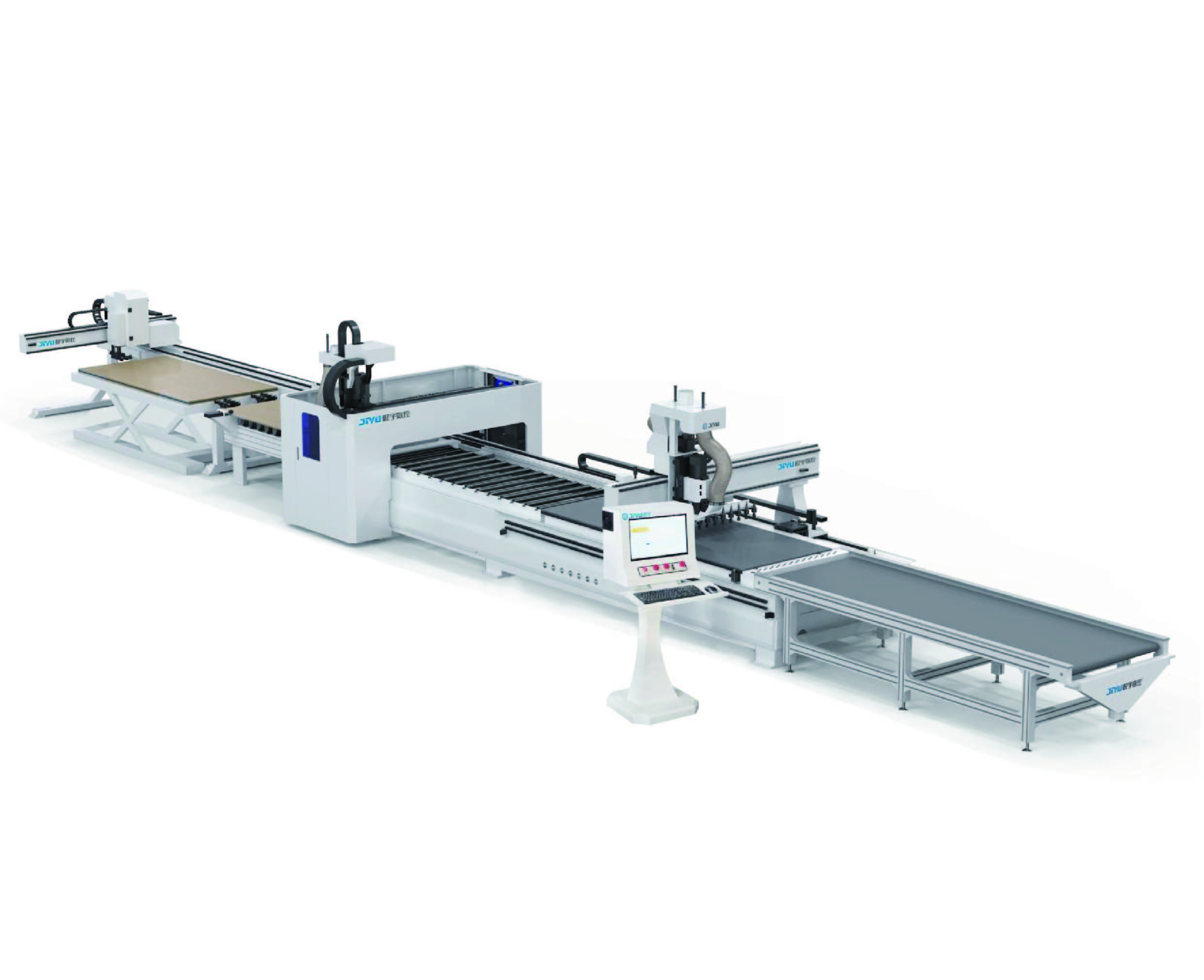

After years of research and development and practice, CNC cutting machines have developed many mature models, such as three-process cutting machines (entry-level), four-process cutting machines, cutting machining centers, dual-spindle row drilling and package machining centers and One spindle, one row of drills, one tool magazine, machining center, etc. The four-process CNC cutting machine is an economical multi-function CNC equipment.

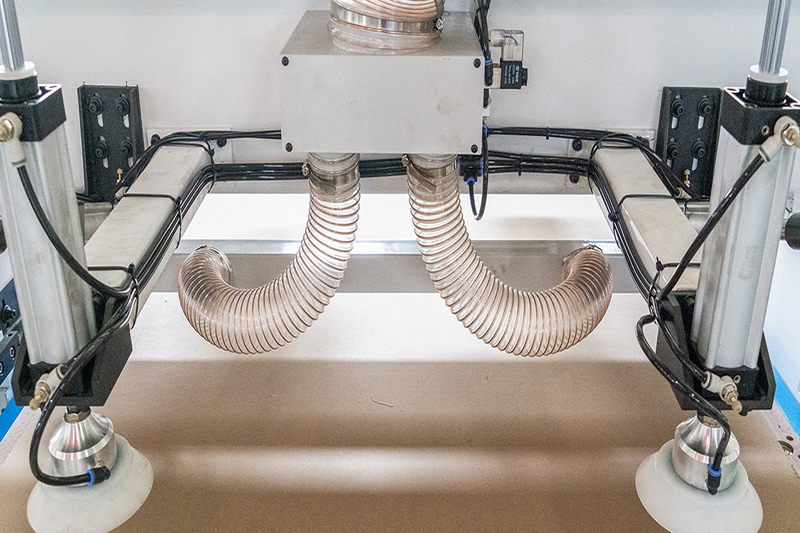

The four-process CNC cutting machine has four spindles. When producing panel furniture, all four spindles can perform drilling processing. Two of the spindles are high-power spindles dedicated to grooving and blanking, and the other two spindles are dedicated to drilling. In this way, the hole sizes usually encountered in the production of panel furniture can be processed. At the same time, the four-process CNC cutting machine can also be well used in the production of cabinet doors.

All four spindles can be used to make door shapes. When the door shape requires four or less knife types, all Can be processed with pneumatic tool changer. At present, there are relatively few manufacturers using the four-step process, and the price/performance ratio is not very high. However, the four-step cutting machine is relatively good in terms of comprehensive application.

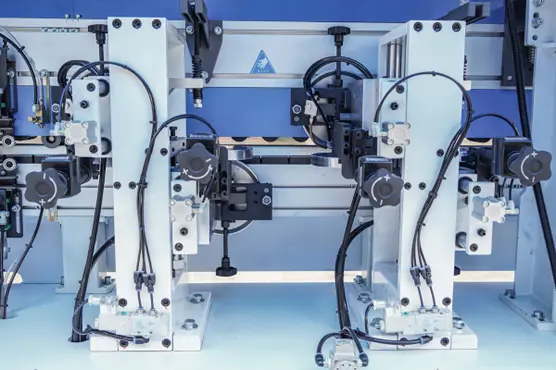

Choosing a woodworking cutting machine must meet our production requirements, determine our own production process requirements, the output needs of the automatic furniture factory, determine the budget for equipment investment, and select a model with an appropriate price through comprehensive consideration of all aspects. After determining the model, you need to consider the quality of the equipment, buy the right product at the right price, and pursue a cost-effective product. Choose a high-quality product by examining the strength of the equipment manufacturing factory, the core accessories of the machine (including control systems, drive systems, racks, guide rails, reducers, frequency converters, electrical components, pneumatic parts, etc.), and the manufacturer's service quality.